-

- Wire and cable concealment

- Kitchen mouldings

-

- door- and window gasket with groove

- Self-adhesive universal gaskets + door and window gaskets w. sealing strip

- Gaskets for exterior sill, sealing strips and compressed sealing tape

- Gaskets with and without cord

- Accessories for gaskets

- Gaskets for glazing beads and seamless installation

- Clamp gaskets

- Facades – Light covers and casings

- Self-Adhesive Profiles

-

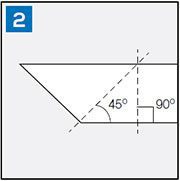

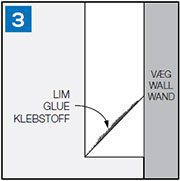

- Installing solid mouldings

- Installing Easy skirtings

- Installing COVER(IT) self-adhesive skirting

- Installing Classic skirting and architraves for concealing cables

- Installing soft fluted skirting

- Installing kitchen mouldings

- Installing glazing beads and gasket clamp profiles

- Installation of FiberCore glazing beads

- Guidelines for bending mouldings

- Catalog

- Contact

- Download Center

-

- Wire and cable concealment

- Kitchen mouldings

-

- door- and window gasket with groove

- Self-adhesive universal gaskets + door and window gaskets w. sealing strip

- Gaskets for exterior sill, sealing strips and compressed sealing tape

- Gaskets with and without cord

- Accessories for gaskets

- Gaskets for glazing beads and seamless installation

- Clamp gaskets

- Facades – Light covers and casings

- Self-Adhesive Profiles

-

- Installing solid mouldings

- Installing Easy skirtings

- Installing COVER(IT) self-adhesive skirting

- Installing Classic skirting and architraves for concealing cables

- Installing soft fluted skirting

- Installing kitchen mouldings

- Installing glazing beads and gasket clamp profiles

- Installation of FiberCore glazing beads

- Guidelines for bending mouldings

- Catalog

- Contact

- Download Center